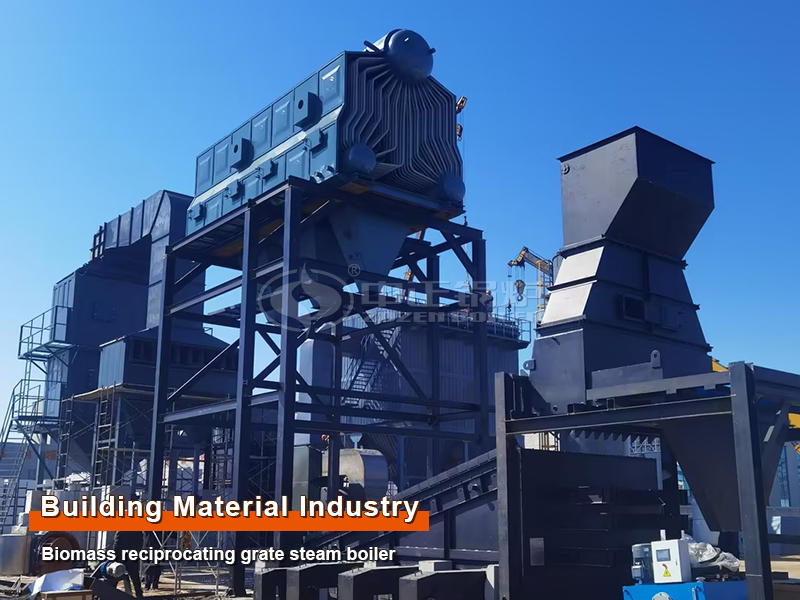

Available industries:Building Material Industry

Project boiler medium:Steam

Capacity:19TPH

Equipment:DZW19-1.6-SS

19-Ton Biomass Reciprocating Grate Steam Boiler in Building Material Industry

Introduction

ZOZEN Boiler has successfully delivered a customized 19-ton biomass reciprocating steam boiler to a building material factory in Shandong, China. This specialized boiler is designed with three drums and features a unique design that prevents ash accumulation.

The client company specializes in manufacturing innovative modular building components, including ALC autoclaved sand-lime panels and AAC autoclaved aerated concrete blocks. The steam boiler plays a crucial role in supporting the production process at the factory. By utilizing biomass particulates as fuel, this boiler significantly reduces energy consumption and minimizes environmental pollution. Furthermore, it provides stable high-temperature steam, ensuring efficient production and high-quality output of aerated panels and concrete blocks. These improvements greatly enhance the factory’s competitiveness in the building material industry.

ZOZEN Boiler excels in providing tailored boiler solutions based on the specific needs of each customer. In this case, a reciprocating grate three-drum steam boiler was selected, offering enhanced fuel utilization efficiency and an extended lifespan. Additionally, this solution effectively addresses the common challenges associated with ash accumulation and cleaning difficulties often encountered when utilizing biomass fuels in traditional boilers.

By partnering with ZOZEN Boiler, the building material factory in Shandong has received a customized biomass steam boiler that meets their unique requirements, resulting in improved energy efficiency, reduced environmental impact, and enhanced production capabilities.