Brand Name: ZOZEN

Certification: ISO, CE, ASME

Model Number: WNS6-1.25-Q

Minimum Order Quantity: 1 set

Price: Contact Aileen for Latest Price

Payment Terms: L/C, T/T

Packaging: Nude packing with foam for boiler body, wooden case for boiler accessories.

Detail Information

- Output: Steam

- Steam Capacity: 6 Ton Per Hour, 6000kg/hr, 6tph, 3600000kcal, 4200kw

- Fuel Design: Nature gas, coke oven gas, biogas, liquid propane gas, diesel, heavy oil, light oil, crude oil, etc.

- Design Pressure: 0.7-2 Mpa (7bar to 20bar)

- Warranty: 1 Year

- Structure: 3 Pass Fire Tube Wet Back Boiler

- Factory: ZOZEN boiler Co., Ltd.

- Application: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

- Style: Horizontal

- Design Efficiency: High Effciency 95%-99%

- Condition: New

- Use: Industrial

- Product Name: 6 Ton Capacity Gas Fuel Fire Tube Steam Boiler

Gas Fired Steam Boiler Introduction

Industrial WNS series oil fired boilers have reasonable price, guaranteed quality, direct supply from source sales mode, sufficient supply, high cost performance. WNS series steam boiler is designed with three-return thread smoke tube, large fuel combustion in furnace and high thermal efficiency. Fully automatic control operation ensures lower energy consumption of the boiler. In terms of safety, it is equipped with multiple interlock protection and aluminum silicate double layer insulation effect to reduce heat loss of the boiler.

Technical advantages

- The key part such as material cutting, rolling, drilling are proceeded by advanced CNC machining process to reduce the assemble stress and extend boiler working lifetime.

- The front and back smoke chamber plates are cut by CNC plasma cutting machine and looks tidy and beautiful.

- Fully automatically operating, with automatically adjustment and protection of burning, water level, temperature and steam pressure.

- Smoke tube and tube sheet connection is expanded first to eliminate the gap between them, then adopt automatic argon arc welding to relief the stress and expand boilers working life.

- Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint will have 100% radiographic inspection.

- Fin tube us ND steel or stainless-steel material which avoid low temperature corrosion.

- Inspection procedure point is set up to guarantee the sequence of expanding and welding, avoid cracking of the tube sheet holes.

- High quality aluminum silicate fiber is used with fire clay insulation, to control the boiler body temperature below 45℃ to control heat lost.

- Sufficient steam storage room and heating area makes boiler to generate high quality steam and high thermal power.

- Condenser is added to reuse the waste heat of the exhausted smoke to increase feeding water’s temperature and reduce emission temperature, which can increase the thermal efficiency above 98% and save operating cost.

Digitized manufacture

Easy operation and maintenance

Longer working life

Less fuel consumption

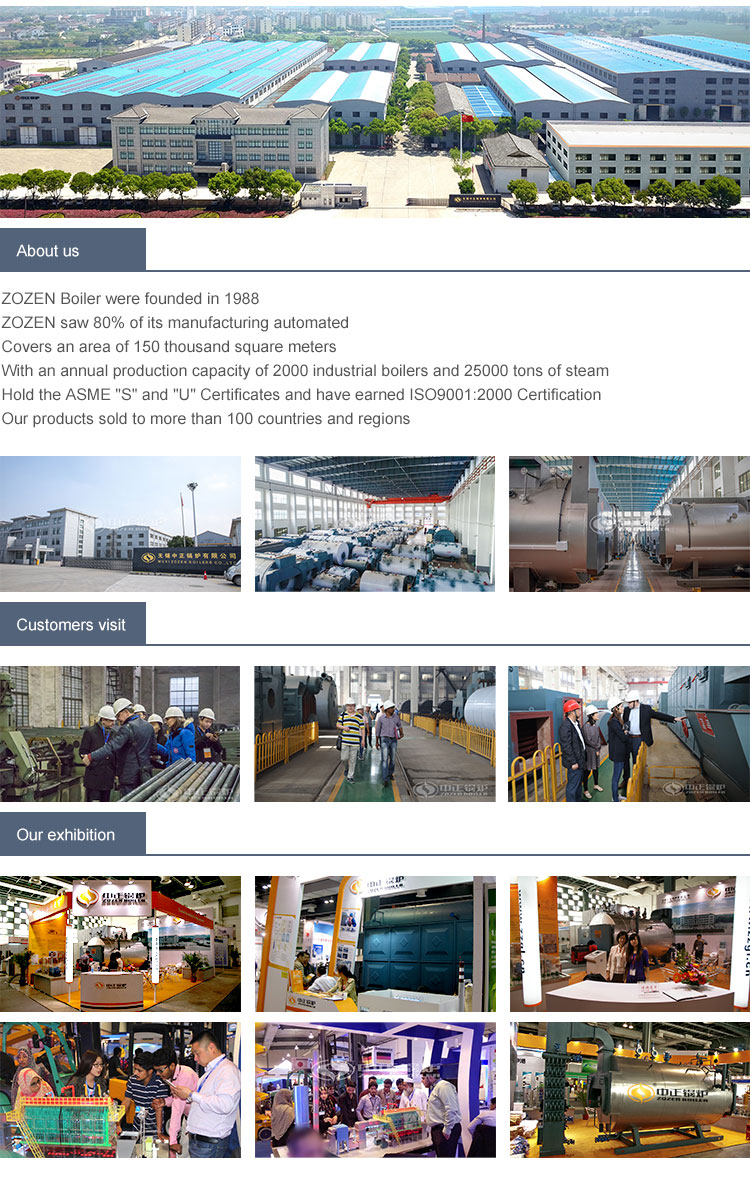

ZOZEN Factory

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2000 international quality system certification. The company gained the ” S ” and ” U ” steel seal from ASME of US.