Available industries:Tobacco Industry

Project boiler medium:Steam

Capacity:6 tph

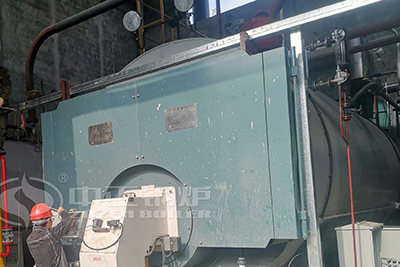

Equipment:SZL6-1.25-AII

6 Tons Coal-Fired Steam Boiler in Indonesia Tobacco Industry

Introduction

The tobacco processing industry is renowned for its energy-intensive operations, particularly in terms of steam demand for drying and humidifying processes. The stability and quality of the energy supply directly impact the final product’s quality. Therefore, selecting a boiler system capable of meeting high-load operational demands and maximizing energy utilization is vital for tobacco factories.

A tobacco factory located in Surabaya, Indonesia, faced the dual challenge of enhancing production efficiency while reducing energy consumption and emissions. ZOZEN Boiler provided a comprehensive solution tailored to the specific needs of the tobacco factory, offering the SZL series 6 tons coal-fired steam boiler. This boiler not only fulfilled the factory’s steam demand but also demonstrated high efficiency and environmental friendliness throughout its operation. ZOZEN Boiler took into account Surabaya’s climatic characteristics and the availability of local fuel sources during the boiler’s design phase, ensuring stable performance under varying environmental conditions.

With ZOZEN Boiler’s technical support, the client’s tobacco processing line achieved improved energy utilization and reduced environmental emissions. The boiler’s stability and reliability have been thoroughly validated, providing robust support for the enterprise’s ongoing development.

By choosing ZOZEN Boiler the tobacco factory in Surabaya has optimized its production processes, resulting in higher energy efficiency and enhanced environmental sustainability. ZOZEN Boiler’s commitment to delivering tailored solutions and advanced technology has once again proven instrumental in meeting the unique energy demands of the tobacco industry.