Case Introduction

Dyeing and finishing is a chemical process used in the production of textile mills. After chemical treatment, textile materials are subjected to repeated washing and drying processes, which consume a lot of heat and water. To reduce heat consumption, the textile mill purchased a set of YQW series gas-fired thermal oil heater system from ZOZEN Boiler Company. The system has sufficient output power and high thermal efficiency, which can meet the high temperature thermal demand of lace production and dyeing and finishing production line.

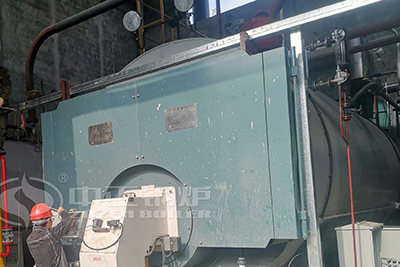

ZOZEN YQW series gas heat conduction oil heater adopts three-way circular coil structure. Conical coil tube is adopted at the end of the coil tube to effectively protect the boiler end furnace and ensure the boiler’s long-term, safe and stable operation. The boiler also adopts countercurrent heat transfer technology, which has good heat transfer effect. Through an efficient heat transfer system at the end of the boiler, the overall thermal efficiency of the boiler can reach more than 95%.

Gas heat conduction oil boiler can use natural gas, coke oven gas, biological gas, liquefied propane gas as fuel, 10 million kcal gas heat conduction oil boiler under different working conditions, can maintain the best thermal efficiency. The 10 million kcal 10 million kcal gas-fired thermal oil heater produced by ZOZEN is a boiler that can produce a maximum of 1 million kcal calories in one hour, so its natural gas consumption is: 1 million divided by the boiler thermal efficiency (94%) divided by the natural gas calorific value (8600 kcal /Nm3)=1237 cubic meters per hour. Of course, this value can only be used as a reference, each boiler project is different, the actual use needs are also different, and the specific gas consumption should be based on the boiler heat output per hour and the actual operation situation.

Customer Feedback

After gaining an in-depth understanding of our production technology, ZOZEN Boiler recommended this type of gas-fired horizontal heat conducting oil heater and offers a complete boiler system solution that fits well with our production line. In addition, the ZOZEN technicians provided us with specific instructions for boiler installation and commissioning. We were impressed by their patience and professional service. Thanks to ZOZEN Boiler!