Boiler is a kind of energy conversion equipment. The energy input to the boiler includes chemical energy and electric energy in fuel, while the boiler outputs steam, high temperature water or organic heat carrier with certain heat energy. The original meaning of the pot refers to the water container heated on the fire, and the furnace refers to the place where fuel is burned. The boiler includes the pot and the furnace. Industrial boilers not only occupy an important position in industrial production, but also cannot be separated from boilers in daily life. At present, the light and textile industry, energy industry, building materials, construction industry, chemical industry, metallurgical industry, transportation industry and military sector will still be the main market of industrial boilers in China’s industrial production. Heating, disinfection, drying and other aspects also need to use boilers, so we need to have a basic understanding of boilers capacity.

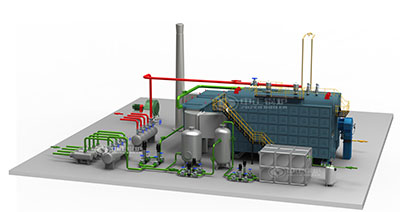

szs boiler system diagram

Boiler capacity and parameters

Boiler capacity refers to the maximum continuous steam produced by the boiler per hour, the unit is t/h or kg/s, also known as the boiler rated evaporation capacity. The rated parameters of the steam boiler refer to the rated steam pressure and rated steam temperature. Rated steam pressure refers to the outlet steam pressure that should be guaranteed in the long term continuous operation within the specified feed water pressure and specified load range of the steam boiler, MPa per unit time. Rated steam temperature refers to the steam boiler in the specified load range, rated steam pressure and rated feed water temperature under the long-term continuous operation must ensure that the outlet steam temperature, the unit is ℃.

Classification of boilers

- According to the boiler use classification: power boilers include power station boilers, ship boilers and locomotive boilers, etc., corresponding for power generation, ship power and locomotive power. Heating boilers include steam boiler, hot water boiler, heat pipe boiler, hot air furnace and heat carrier furnace, etc., and obtain steam and hot water accordingly.

- According to the boiler structure classification: mainly divided into fire tube boiler and water tube boiler. Fire tube boiler includes vertical boiler and horizontal boiler, water tube boiler includes horizontal tube boiler and vertical tube boiler.

- According to the type of boiler fuel, it is divided into coal-fired boilers, oil-fired boilers, gas-fired boilers and the upgrading technology of coal-fired boilers, and the replacement products of oil-gas boilers — pulverized coal boilers, dual-use gas boilers and so on. Coal – fired boilers can be divided into layer – fired boiler, chamber – fired boiler and boiling boiler.

- According to boiler capacity classification: evaporation less than 20t/h is called small boiler, evaporation more than 75t/h is called large boiler, evaporation between the two called medium boilers.

- According to boiler pressure classification: below 2.5MPa boiler is called low-pressure boiler, 6.0MPa or more is called high pressure boiler, pressure between the two is called medium pressure boiler. In addition, there are ultra-high pressure boilers, subcritical boilers and supercritical boilers.

- According to the boiler water cycle form classification: according to the boiler water cycle form can be divided into natural cycle boiler and forced cycle boiler (including dc boiler).

- According to the form of equipment classification: can be divided into quick loading boiler, assembly boiler and bulk boiler.

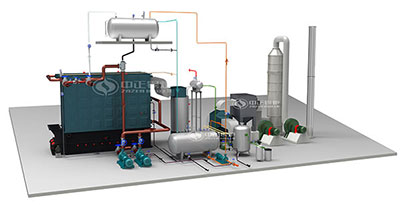

ylw boiler system diagram

With more than 30 years of industrial boiler design and manufacturing experience, ZOZEN Boiler has become a reliable partner in all walks of life. Our production base covers an area of 120000 square meters, the company registered capital of 127 million yuan, AAA grade credit enterprise, has yearly produces 2000 sets of industrial boiler, 25000 steam ton, with 59 patents, holding A class boiler manufacturing license, BR Ⅱ class pressure vessel manufacturing license, American ASME standard “S” (power boiler), “U” (pressure vessel) licensing steel seal, and fully passed ISO9001:2000 international quality system certification.