Inquiry Email: zhulin@zozen.com

The brewery industry requires a large amount of steam for distillation and fermentation, with high requirements for the amount and quality of steam per unit of time, regardless of the size of the brewery, steam boilers are needed in the process. From the perspective of environmental protection, most of the brewery boilers use oil gas boilers, ZOZEN manufacturing WNS series condensing boiler is a new environmentally friendly, energy-saving industrial boiler products, the body of the boiler using the corrugated furnace gall can effectively increase the radiation heating surface, the configuration of the perfect energy-saving equipment boiler thermal efficiency can reach 98%, effectively saving fuel costs for enterprises.

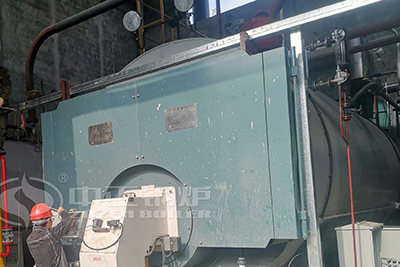

The brewery customer purchased two sets of WNS series 10-ton gas-fired steam boilers manufactured by ZOZEN to provide high stable and high quality steam for the liquor production line. The 10 ton fire tube boiler system solution was customized for the customer by carefully analyzing the actual steam consumption of the brewery production line, using natural gas as fuel. This boiler can be used for a wide range of fuels, both gas and oil, and can also be mixed with oil and gas to meet a variety of customer needs. When designing the boiler system, the appropriate burner can be selected according to the actual fuel requirements.

The gas-fired steam boilers are designed with a large-diameter furnace chamber and a large steam ladle space, which allows them to store sufficient steam, while the low water content of the steam results in higher quality steam, which meets the brewing industry’s requirements for high-quality steam. After the two sets of boilers were delivered to the brewery project site for installation and operation, the customer expressed great satisfaction with the cooperation process with ZOZEN. The two sets of steam boilers produced by ZOZEN have a small footprint and are relatively compact, and the boilers are shipped in a complete package, which is easy to install once they arrive at the project site. At present, the steam supply is already normal and we can operate them easily, thanks to ZOZEN boilers.

The fire tube boiler with oil gas fuel is also equipped with intelligent technologies such as automatic water level alarm, automatic feed water adjustment, programmed start-stop, etc., which can automatically start the automatic protection function when the alarm water level is high or low or the steam pressure is super high, effectively improving the service life of the boiler. With the development of the industrial boiler industry, there are many models and types of oil and gas boilers, and the process of purchasing boilers can be based on the actual needs of the production line, the pursuit of more cost-effective steam boilers.

With more than 30 years of experience in steam boiler and hot water boiler production, ZOZEN boiler factory is a well-known industrial boiler brand. The boiler production base has 6 automated processes, and the digital discharging process effectively reduces process errors to ensure boiler quality. Through the continuous efforts of ZOZEN team, the boiler products are sold to more than 100 countries and regions (Malaysia, Turkey, Bangladesh, Uzbekistan, Thailand, Venezuela, Philippines, Saudi Arabia, Indonesia, etc.) with 15580 successful cases, providing steam boilers with different fuels for paper industry, chemical industry, food industry, central heating, etc. ZOZEN has Class A boiler manufacturing license and Class A pressure vessel design and manufacturing license, ISO 9001 quality system certification and American ASME S (boiler) & ASME U (pressure vessel) design and manufacturing license, which allows customers to choose ZOZEN as boiler supplier with confidence.