Brand Name: ZOZEN

Certification: ISO, CE, ASME

Model Number: SZS series

Minimum Order Quantity: 1 set

Price: Contact us for Latest Price

Payment Terms: L/C, T/T

Packaging: Nude packing with foam for boiler body, wooden case for boiler accessories.

Detail Information

- Output: Steam

- Steam Capacity: 10 ton, 15 ton, 20 ton, 25 ton, 30 ton, 35 ton, 40 ton and etc.

- Fuel Design: Nature gas, coke oven gas, blast furnace gas, carbon black off-gas, biogas, LPG, diesel, heavy oil, light oil, crude oil, etc.

- Design Pressure: 1.25 – 2.5Mpa(12.5 bar to 25 bar)

- Warranty: 1 Year

- Structure: Water Tube

- Factory: ZOZEN boiler Co., Ltd.

- Application: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

- Style: Horizontal

- Design Efficiency: High Effciency 95%-99%

- Condition: New

- Use: Industrial

- Product Name: Natural Gas Diesel Oil Fired Steam Boiler

Typical Projects

10 tph fire tube boiler for paper mill

60 ton steam boiler for chemical plant

30 ton oil gas boiler for coking industry

SZS Series Water Tube Boiler Introduction

- Model: SZS

- Capacity: 20 – 110 ton per hour

- Design pressure: 0.7Mpa 1.0Mpa 1.25Mpa 1.6Mpa 2.5Mpa(7 bar/10 bar/12.5 bar/16 bar/25bar)

- Stem temperature: 194 – 540 °C

- Design fuel: natural gas, lpg,lng,cng,city gas,biogas, diesel oil,heavy oil,etc

SZS series oil gas fired water tube boiler adopts double-drum “D-type” vertical arrangement, full-membrane wall structure, reasonable and compact layout, can realize large-capacity boiler overall quick installation, less investment in boiler house infrastructure and short installation period.

Core technology

- Nitrogen oxide emissions <30mg/m3;

- Full water membrane wall structure;

- Compound water circulation structure;

- Cascade utilization of waste heat from flue gas;

- Cascade utilization of waste heat from flue gas;

- Aluminum silicate insulation layer;

Product Parameters

| Model | Rated evaporation(t/h) | Rated working pressure(MPa) | Rated steam temperature(℃) | Thermal efficiency(%) | Maximum transport size(m) (L×W×H) |

| SZS20-1.25-Q.Y | 20 | 1.25 | 194 | >98 | 8.9×3.9×4.0 |

| SZS20-1.6-Q.Y | 20 | 1.6 | 204 | >98 | 8.9×3.9×4.0 |

| SZS20-2.5-Q.Y | 20 | 2.5 | 225 | >98 | 8.9×3.9×4.0 |

| SZS25-1.25-Q.Y | 25 | 1.25 | 194 | >98 | 10.5×4.2×4.2 |

| SZS25-1.6-Q.Y | 25 | 1.6 | 204 | >98 | 10.5×4.2×4.2 |

| SZS25-2.5-Q.Y | 25 | 2.5 | 225 | >98 | 10.5×4.2×4.2 |

| SZS30-1.25-Q.Y | 30 | 1.25 | 194 | >98 | 10.5×4.3×4.3 |

| SZS30-1.6-Q.Y | 30 | 1.6 | 204 | >98 | 10.5×4.3×4.3 |

| SZS30-2.5-Q.Y | 30 | 2.5 | 225 | >98 | 10.5×4.3×4.3 |

| SZS35-1.25-Q.Y | 35 | 1.25 | 194 | >98 | 11.3×4.3×4.3 |

| SZS35-1.6-Q.Y | 35 | 1.6 | 204 | >98 | 11.3×4.3×4.3 |

| SZS35-2.5-Q.Y | 35 | 2.5 | 225 | >98 | 11.3×4.3×4.3 |

| SZS40-1.25-Q.Y | 40 | 1.25 | 194 | >98 | 12.4×4.4×4.6 |

| SZS40-1.6-Q.Y | 40 | 1.6 | 204 | >98 | 12.4×4.4×4.6 |

| SZS40-2.5-Q.Y | 40 | 2.5 | 225 | >98 | 12.4×4.4×4.6 |

| SZS50-1.25-Q.Y | 50 | 1.25 | 194 | >98 | 15.6×4.4×4.6 |

| SZS50-1.6-Q.Y | 50 | 1.6 | 204 | >98 | 15.6×4.4×4.6 |

| SZS50-2.5-Q.Y | 50 | 2.5 | 225 | >98 | 15.6×4.4×4.6 |

| SZS65-1.25-Q.Y | 65 | 1.25 | 194 | >98 | 11.5×1.5×1.8 |

| SZS65-1.6-Q.Y | 65 | 1.6 | 204 | >98 | 11.5×1.5×1.8 |

| SZS65-2.5-Q.Y | 65 | 2.5 | 225 | >98 | 11.5×1.5×1.8 |

| SZS75-1.25-Q.Y | 75 | 1.25 | 194 | >98 | 12×1.5×1.8 |

| SZS75-1.6-Q.Y | 75 | 1.6 | 204 | >98 | 12×1.5×1.8 |

| SZS75-2.5-Q.Y | 75 | 2.5 | 225 | >98 | 12×1.5×1.8 |

| SZS100-1.25-Q.Y | 100 | 1.25 | 194 | >98 | 13×1.5×1.8 |

| SZS100-1.6-Q.Y | 100 | 1.6 | 204 | >98 | 13×1.5×1.8 |

| SZS100-2.5-Q.Y | 100 | 2.5 | 225 | >98 | 13×1.5×1.8 |

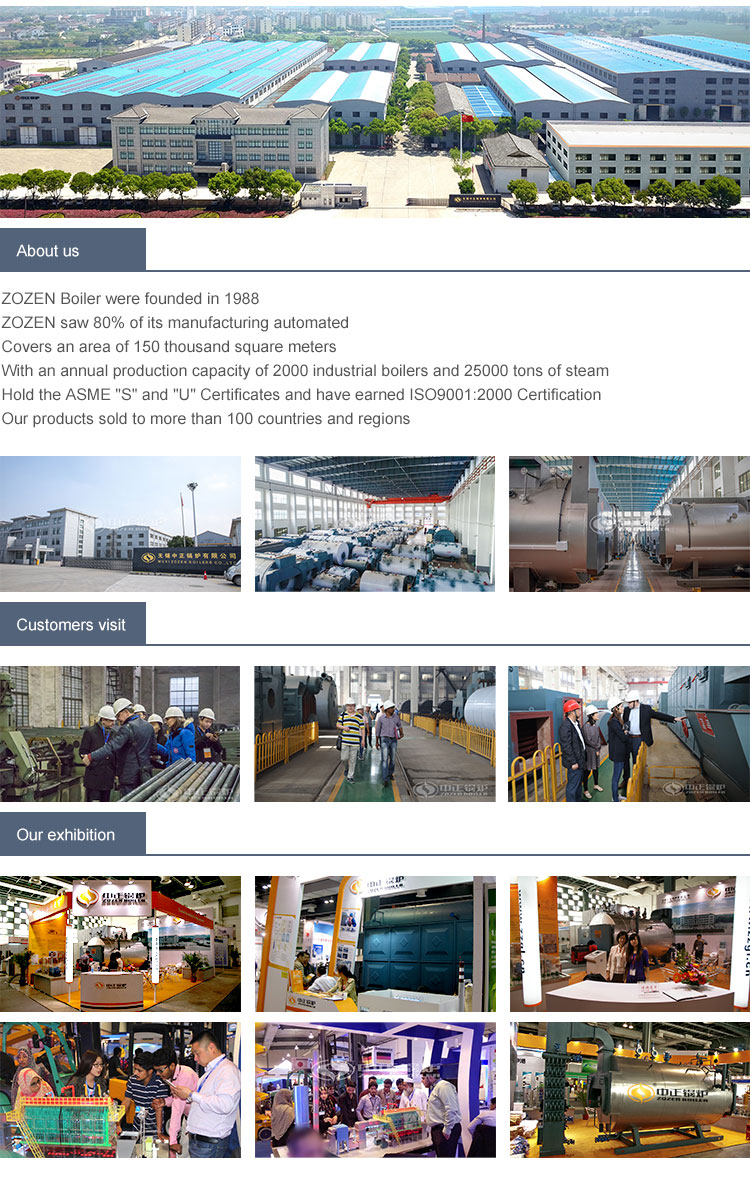

ZOZEN Factory

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2000 international quality system certification. The company gained the ” S ” and ” U ” steel seal from ASME of US.

Pre-sale service:

-

- We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

-

- We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

- provide full range of original spare parts.

- Engineers abroad installation and commissioning service is available.

- Our engineers will held a training for boiler workers to ensure the safe operation.

- Free maintenance and repair for one year and lifelong service.