ZOZEN boiler factory’s fire tube boiler is WNS series oil gas boilers. These boilers work originally with high temperature flue gas flowing from the burner through the threaded flue tube surrounded by water, heating the water, steam or steam-water mixture outside the wall of the flue tube to produce steam or hot water, and are divided into two-pass and three-pass fire tube boilers according to the flue gas stroke. ZOZEN can provide WNS series fire tube boiler with capacity from 1 ton to 20 tons, which are more suitable for the production of small and medium-sized enterprises that value environmental protection.

ZOZEN as a manufacturer with more than 30 years of experience in designing and manufacturing industrial boilers for various industries, including chemical, pharmaceutical, paper, textile, food, electronics, automobile manufacturing and other industries. The fuel of 1 tph – 20 tph fire tube boiler is widely adapted to gas fuels such as natural gas, coke oven gas, biogas, and liquid fuels such as methanol, diesel, heavy oil, light oil, residual oil. WNS series steam boilers are simple in structure, convenient in manufacture and short in installation period. It is a typical quick-assembly boiler, where the installation of the whole boiler is completed in the factory, and only a simple connection of external water and electricity is needed to put it into operation after delivery to the boiler room, which greatly shortens the installation and commissioning time.

gas fuel fire tube boiler

Gas fuel fire tube boilers provide a large amount of high-quality steam for efficient production in the semiconductor industry. ZOZEN provides 20 ton gas fired steam boilers as heating equipment, and the stable and efficient operation effectively ensures product quality. This WNS series oil gas fired boiler adopts large diameter corrugated furnace liner, which enhances the flue gas interference and effectively improves the heat transfer effect of flue gas; according to the actual use requirements of production line, the boiler flue tail will be equipped with energy saver to reduce the exhaust temperature as low as 60 degrees Celsius (140 degrees Fahrenheit), and the boiler thermal efficiency can reach 98% under the best circumstances.

The 20 ton condensing boiler selected by the semiconductor industry is essential as a heat source equipment in the drying process of various finished electronic components. This WNS type steam selects advanced low-NOx burner, and optimizes the design and technical innovation of furnace chamber size, volumetric heat load, and flue gas flow rate in convection zone to ensure the NOx emission of the boiler is lower than 30mg/Nm3. ZOZEN Boiler’s design team customized the WNS series three-return gas steam low-NOx boiler system according to the actual needs of the customer’s production, which significantly reduces the production cost and improves the economic efficiency of the company for Electronic Technology. With the significant advantages of WNS series gas boilers, ZOZEN boilers have gained the trust of many companies in the electronics industry.

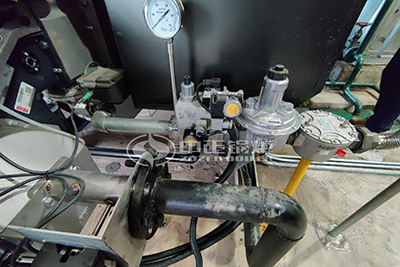

accessories of gas fired boiler

Relying on the advanced automatic production line and technical advantages, ZOZEN Boiler not only creates several series of high quality fire tube boiler for sale, which are widely promoted and applied in various industries, but also customizes fire tube boiler systems for enterprises to meet different needs of users and provides one-stop service from design, manufacture, installation, commissioning to training. ZOZEN has agents in Bangladesh, Pakistan and Turkey in many countries. If you are looking for high quality boiler products, please feel free to contact us through online inquiry, WhatsApp, email and other ways.