Food companies need steam boilers to provide high quality steam for cooking, distillation, sterilization, drying and other processes during the processing of meat products. As we all know, the food industry attaches great importance to food safety, so it has high requirements for the steam produced by industrial steam boilers and the stable operation of the boilers.

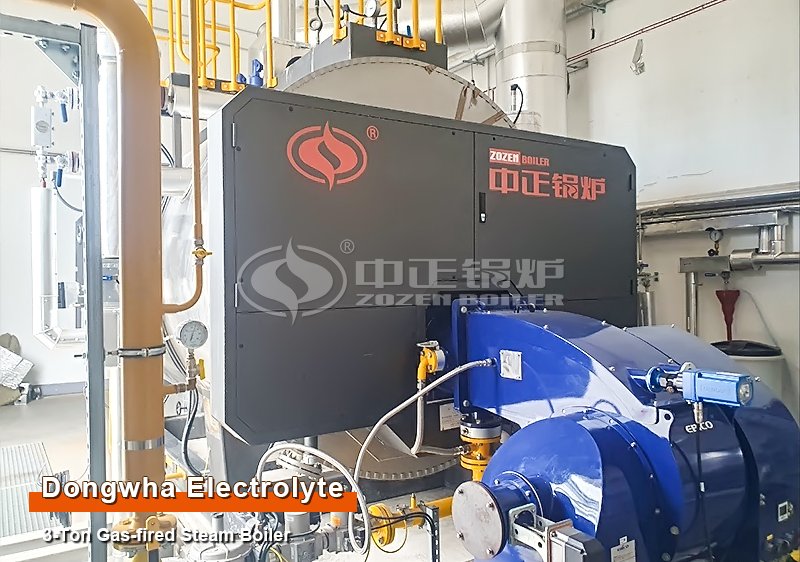

Based on the actual requirements provided by the customer and ZOZEN’s service experience in the food industry, engineers recommended the WNS series gas boiler for the customer. This steam boiler 2 tons per hour uses clean energy as fuel and does not require separate fuel storage, which has the advantages of energy saving, high thermal efficiency, safety and environmental protection, and is suitable for various industrial production processes.

WNS series gas has a wide range of fuel applicability for gas boilers, and users can choose the right fuel according to actual production. The series boiler adopts high efficiency heat transfer element threaded flue tube, which can effectively improve the thermal efficiency of the boiler, reduce material loss, prolong the service life of the boiler, and effectively reduce the operating cost. ZOZEN’s oil-fired gas boiler adopts advanced low nitrogen burner to ensure full combustion of fuel, which not only saves fuel for users, but also plays a certain role in protecting the environment.

The customer said that the steam output of this 2 ton steam boiler is stable and it is very important heat source equipment for the production line. The boiler is delivered to the food factory and can be put into operation by simply connecting water and electricity, saving the installation cost for the company. ZOZEN Boiler also provided us with professional boiler installation and commissioning training guidance, and the professional and comprehensive service is very satisfactory.