When it comes to understanding the most basic difference between steam generator vs boiler, which both generate energy through steam, it can be confusing. However, they achieve this goal in fundamentally different ways, affecting various aspects of each system, including their design, operation, and, most importantly, applications.

Steam Generator vs Boiler Design and Structure:

Compared to boilers, steam generators incorporate fewer built-in steel materials in their design and use a single coil instead of numerous smaller-diameter boiler tubes. A dedicated feed-water pump is used to continuously pump the feed-water through the coil. Steam generators employ a once-through, forced-flow design, converting the incoming water into steam in a single pass through the water coil. As water passes through the coil, heat is transferred from the hot gases, resulting in the conversion of water into steam.

As generators do not utilize large pressure vessels like fire-tubes in boilers, they are typically smaller and have faster startup times, making them an ideal choice for rapid-demand situations. However, this comes at the cost of energy production as generators have low turn-down rates, resulting in poorer steam supply capability during demand fluctuations.

Steam Generator vs Boiler Working Pressure and Temperature:

Steam generators produce steam at relatively lower pressures and temperatures, suited for applications where moderate energy is required. On the other hand, boilers are capable of producing steam at higher pressures and temperatures, meeting the demands of large power plants and industrial processes that require high-energy outputs.

Steam Generator vs Boiler Application Areas:

Steam generators find their application in smaller-scale operations, laboratories, heating systems, and specialized processes such as hot water supply, fluid heating, and laboratory use. They are known for their compactness, ease of installation, and versatility in meeting moderate steam demands.

Boilers are primarily employed in heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital where substantial amounts of high-pressure steam are needed for power generation and heating purposes.

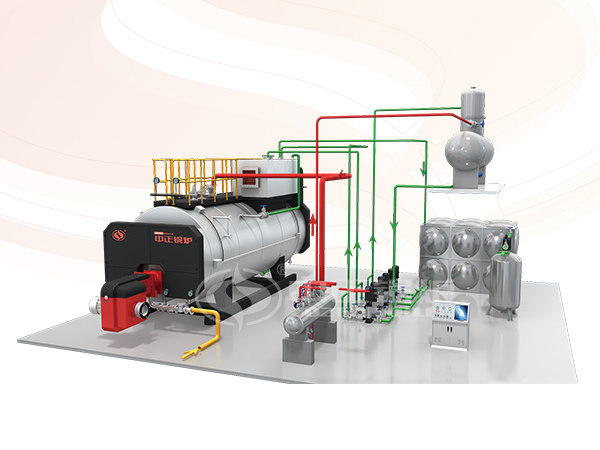

Introducing the ZOZEN Boiler WNS Series Gas-fired Steam Boiler:

In the realm of boilers, the ZOZEN Boiler WNS Series gas-fired steam boiler stands out with its exceptional product features and advantages. This boiler series offers efficient and reliable performance, making it a preferred choice for various industrial and commercial applications. With a robust design and advanced combustion technology, the WNS Series ensures optimized fuel utilization, reduced emissions, and enhanced energy efficiency. Its intelligent control system allows for precise temperature and pressure control, ensuring safe and stable operation. Furthermore, the boiler’s compact footprint and quick start-up time make it suitable for fast-demand scenarios while maintaining high steam supply capability.

Furthermore, ZOZEN establishes a new industry standard for professional services. From boiler system design to post-sales support, our comprehensive, round-the-clock, end-to-end service system provides our clients with complete support for their business needs.

In summary, understanding the distinctions between steam generator vs boiler is crucial for selecting the right system for specific applications. While steam generators excel in compactness and quick start-up, boilers offer higher pressure and temperature capabilities for larger-scale operations. The ZOZEN Boiler WNS Series gas fired steam boiler enhances these advantages with its outstanding features, guaranteeing reliable, efficient, and safe steam generation.