Dive into the significance of a steam boiler system diagram and its vital components. Learn about ZOZEN Boiler’s industry-leading expertise, advanced production processes, and unmatched after-sales service. Explore the exceptional features of ZOZEN’s WNS series gas steam boiler, including the spacious furnace chamber, energy-saving technologies, and low nitrogen combustion, and uncover the diverse applications of steam boiler systems.

Part 1: The Significance of a Steam Boiler System Diagram

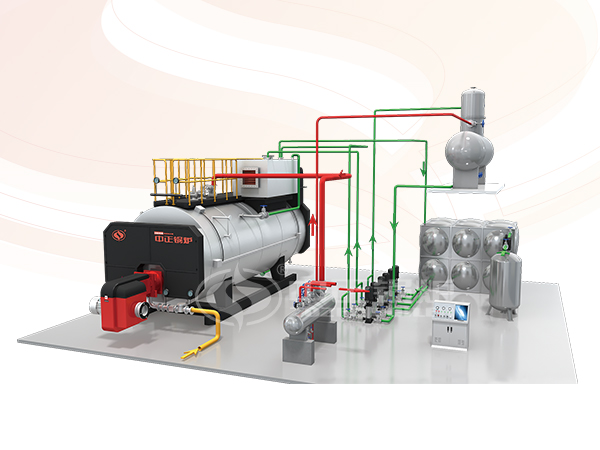

A steam boiler system diagram serves as a visual representation of the complex inner workings of a steam boiler. It provides a comprehensive overview of the system’s components and their interconnections, enabling technicians, engineers, and operators to grasp the system’s functionality and troubleshoot issues effectively. This diagram plays a pivotal role in ensuring the optimal performance and safety of steam boiler systems.

Part 2: Understanding the Basics and Introducing ZOZEN’s Expertise

ZOZEN Boiler is an industry leader known for its commitment to excellence and expertise in steam boiler systems. With essential components like the boiler body, burner, economizer, and control system, they generate heat through fuel combustion, transfer it to water, and produce steam. Backed by cutting-edge manufacturing facilities, ZOZEN’s large-scale production capacity ensures timely delivery of high-quality steam boiler systems that surpass customer expectations. They uphold the highest industry standards through advanced production processes and offer comprehensive one-stop service, including installation guidance, maintenance support, and technical training, ensuring customer satisfaction and success.

ZOZEN WNS series steam boiler system diagram

Part 3: The Exemplary WNS Series Gas Steam Boiler

As a testament to ZOZEN’s innovation and efficiency, let’s explore the remarkable features of their renowned WNS series gas steam boiler.

- Spacious Furnace Chamber with Corrugated Furnace: The WNS series boasts a large-capacity furnace chamber with a corrugated design. This innovative design provides abundant steam storage space and a substantial heating surface, resulting in high thermal power and the production of high-quality steam. The corrugated furnace enhances flue gas disturbance, optimizing heat transfer efficiency and enhancing the furnace’s structural integrity, effectively reducing thermal expansion stress.

- Energy-Saving Devices and Condensers: ZOZEN’s WNS series incorporates energy-saving devices and condensers. These technologies harness the waste heat from flue gases, increasing the feedwater temperature and reducing exhaust gas temperatures. This process significantly boosts the boiler’s thermal efficiency, leading to substantial energy savings.

- Low-Nitrogen Burner and Advanced Combustion Technology: ZOZEN’s WNS series is equipped with low-nitrogen burners and advanced combustion technology. These features ensure that nitrogen oxide (NOx) emissions are ≤30mg/Nm³, meeting and surpassing stringent environmental regulations.

Part 4: The Wide-Ranging Applications of Steam Boiler Systems

Steam boiler systems find extensive applications across diverse industries. They are vital for power generation in electric power plants, provide essential process heating in chemical plants, and power steam-driven machinery in textile factories. These systems are also crucial in food processing, paper manufacturing, and many other industrial processes. The versatility and reliability of steam boiler systems make them indispensable for various applications worldwide.

Explore the power of ZOZEN Boiler‘s WNS series gas steam boiler system diagram, featuring remarkable components such as the spacious furnace chamber, energy-saving technologies, and low nitrogen combustion. Embrace the diverse applications of steam boiler systems across multiple industries, relying on ZOZEN’s expertise for optimal performance and long-term success.